Our Services

ENGINEERING

“From concept to creation”

In order to provide our clients with World-class and comprehensive Engineering Services, TOPETECH-ENERGY became an exclusive agent for some leading international creditable engineering firm to cover a wide range of Offshore and Onshore engineering from its offices in London/ Dubai / Mumbai / Houston.

With Our multi-discipline engineers and project managers assist clients throughout the asset/project life-cycle. We can add value during the planning phases of projects by leveraging our significant Engineering experience. As a result, our designs and modifications are safe, reliable, and aligned with client operational and financial objectives.

CONCEPT DEVELOPMENT

Several offshore marginal discoveries, which weren’t considered economic at the time of discovery, has begun to produce within the last decade because engineering shown a great interest in marginal fields development, that needs innovative technical solutions includes lightweight structure, Monopod Wellhead Platforms, tripod Wellhead Platforms, and other many creative solutions.

The conceptual work includes studies in the early stages of project development for both Greenfield units and Brownfield modifications. The studies can consist of Field Development, Basic Engineering, Process Simulation, Budgeting, and determination of techno-commercial viability of projects and provides decision support to the stakeholders.

Many options need to be evaluated during the concept phase before a large investment in engineering time is made. Typically, a base case is established, and other options are compared to the base case. An extensive cost database is used to compare the options and select the most economical path forward.

FEASIBILITY STUDIES

The engineers assess the proposed project’s strengths and weaknesses and provide options to achieve an optimal technical solution and improve profitability. We offer a techno-commercial feasibility report to the Clients covering the following aspects critical for investment decision:

- Development Planning

- Facility configuration

- Technology selection

- Execution Model Development

- Preliminary Cost Estimation

- Environment Impact assessment

- Economic Modelling

- Risk assessment

- Financial Closure

FRONT END ENGINEERING DESIGN ( FEED )

During the FEED phase, the project schedule, tendering philosophy, risk mitigation strategy, work breakdown structure, and detailed cost estimates are developed to plan the procurement and construction phase. All process engineering is completed along with the mechanical engineering requirements necessary to proceed to the Detailed Engineering and Construction phase.

The FEED deliverables include the following:

- Equipment sizing, materials of construction and design temperatures and pressures.

- Process control requirements, including any analyzers, programmable logic controllers, safety instrumented systems, etc.

- Piping and Instrument Diagrams (P&ID’s)

- Plot Plan

- Final Heat and Material Balances (H&MB’s)

- Process safety contingency analyses

- Utility loads (e.g., steam, cooling water, waste water treating, etc.)

- Interconnections with other units (onsite and offsite)

DETAILED ENGINEERING

Our Engineering Partner have a robust engineering team with track record of delivering more than 500 global assignments successfully. All the disciplines are in-house e.g.

- Process Engineering

- Mechanical Engineering

- Piping Engineering

- Civil & Structural Engineering

- Electrical Engineering

- Instrumentation Engineering

- Safety Engineering

- Risk Management

- Specialist Studies

- Asset Integrity

- Environmental Studies

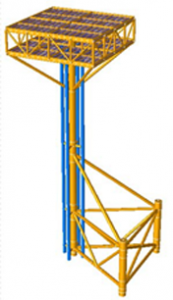

OFFSHORE ENGINEERING

Our offshore Engineering Partner had a wide experience in developing Offshore marginal fields by introducing the following development concepts that provide lower installation cost and can bring production quick: –

- Rig-Installed Wellhead Platforms

- Standard Wellhead Platform Range

- Monopod Wellhead Platforms

- Braced Monopod Wellhead Platforms

- Conventionally Piled Braced Monopod Wellhead Platforms

- Conductor Supported Wellhead Platforms

- Tall Template Wellhead Platform Structures

- Minimal Braced Wellhead Platform Structures

- Wellhead Platform Slot Additions

- MODU Well Bay Modules

- Self-Installing Mini-MOPUs, Wellhead Platforms & Topsides

- Templates and Protection Structures

SUBSEA PIPELINES

Detail engineering, in-place, routing, stability and installation. Riser design, dynamic analysis and cost estimation. Analysis of Fixable Lines and subsea Steel Coiled Line.

Installation analysis

has capabilities to undertake offshore/onshore installation/ construction projects as driveability analysis and heavy lifting calculation. As well as the platform extension to accommodate extra wells pay

We are a Partner with electromechanical fabrication company registered in Egypt. It was established in April 2002 and Has fabrication facilities “Yard” strategically located to serve our core markets in Amireay, Alexandria with Covered Area 3,000 Sq.m, Open Area 4,000 Sq m, Painting & Sand Blasting 2,000 Sq m.